TRI Proteckt®

Proteckt® Energy Absorbing foams (EA), developed by Texas Research Institute Austin, Inc., (TRI Austin) are innovative, high-performing foam appliqués designed to provide soldiers with superior cabin protection in tactical vehicles. The Proteckt® System is cost effective and lightweight, and can be custom designed for any tactical vehicle needing improved safety and protection. Placed in the interior cabin of HMMWVs, FMTVS, and other tactical vehicles, the Proteckt® energy absorbing system has the ability to significantly reduce fatal injuries.

MGA Simulated Mine Blast Test Results

| SAMPLE ID | UPPER LEFT | LOWER LEFT TIBIA Fz (N) | UPPER RIGHT TIBIA Fz (N) | LOWER RIGHT | AVERAGE TIBIA COMPRESSION FORCE (N) | TIBIA FORCE REDUCTION (N) |

|---|---|---|---|---|---|---|

| Steel Plate | 9891 | 10550 | 7661 | 9893 | 9498.75 | -- |

| Competitor 1.25 inch | 9162 | 9357 | 7995 | 8955 | 8867.25 | 631.5 |

| Proteckt 1 inch | 8527 | 8101 | 7418 | 7242 | 7822 | 1676.75 |

| Proteckt 1.5 inch | 8450 | 7535 | 7033 | 6763 | 7445.25 | 2053.5 |

| DATE | SAMPLE DESCRIPTION | PEAK AMP. (G's) | TIME (ms) | ~ V (m/s) | POST-TEST COMMENTS |

|---|---|---|---|---|---|

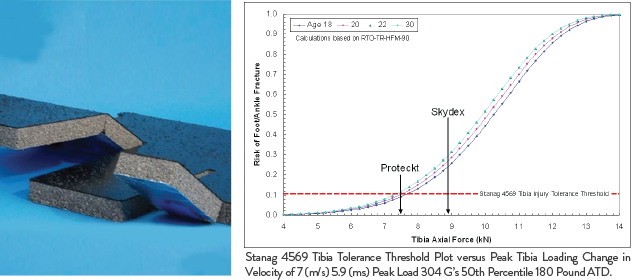

| 6/8/11 | Baseline | 304.7 | 5.9 | 6.96 | No Visible Damage |

| 6/9/11 | Competitor | 304.1 | 5.9 | 6.97 | No Visible Damage |

| 6/9/11 | Proteckt 1" | 303.9 | 5.8 | 6.85 | No Visible Damage |

| 6/9/11 | Proteckt 1.5" | 304.8 | 5.8 | 6.84 | No Visible Damage |

Proteckt® Benefits

- Flooring blast or crash impact mats

- Head impact protection

- Side impact protection

- Seat bottoms

- Under side impact attenuation

Proteckt® Features

- Reduces impact from vehicle rollovers, crashes and IED explosions

- Can be used as blast-mitigating flooring or interior padding

- Provides thermal and acoustic insulation

- No modification to vehicle interior is needed

- Can withstand multiple impacts without degrading performance

- Easy peel-and-stick installation

Product Specifications

| PROPERTY | TEST METHOD | UNITS | VALUE |

|---|---|---|---|

| Density | ASTM-D3575 | psf | 0.58 lbs. (1 inch thick) |

| Thermal Conductivity | ASTM-C177 | (K) BTU-in/ft2-hr-°F | 0.24 |

| Thermal Resistance | ASTM-C177 | (R) @ 70°F | 3.4 per inch |

| Service Temp Range | ASTM-D3575 | °C | -35 to 130 |

| SAE J1400 | ASTM-E90 | - | Pending |

| NRC Rating | ASTM-C423 | - | Pending |

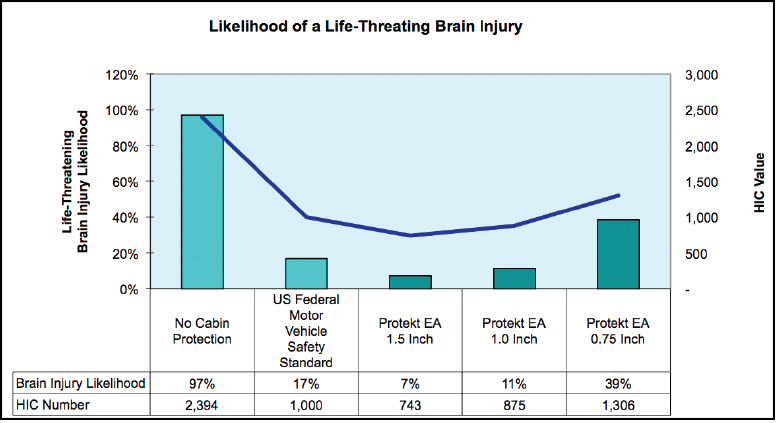

| HIC Rating | FMVSS 201 | Head Injury Criterion | 875 (1" thick) |

| Flammability | FMVSS 302 | Pass/Fail | (FR-EA) Pass - Self Extinguishing 1.5 inch thick (Standard EA) Pass - Self Extinguishing 3/8 thick |

| Compressive Strength @75% | ASTM-D3575 | psi | (Base EA) 111 |

| Tensile Strength | ASTM-D3575 | psi | (Base EA) 67 |

| Water Absorbtion | ASTM-D3575 | % | ~1.0 |

| Dimensions (Thickness) | - | in. | 3/4 to 2 |

| Dimensions (W x L) | - | in. | up to 48 x 72 |

| Slip Test | ASTM-F1677 | Pending | |

| Surface Abrasion Resistance | ASTM-D1044 | % loss | 0.84 after 1,000 cycles |

| Chemical Resistance (Oil, Water, Cleaning Agents, CBW) | TARDEC | Pass/Fail | Pass |

| Salt Fog | ASTM-B-117 | Pass/Fail | Pass |

| Floor Blast ∆ V 7 (m/s) | Stanag 4569 | Risk of foot ankle damage | Pass |

| Toxic Gas Generation | BAA 7239/ABD0031 | Pass/Fail | Pass |